News Details

A special steel enterprise specializing in the production, research and development and sales of high alloy steel forgings

03

2022

-

11

Basic knowledge of normalizing, annealing, quenching and tempering

Author:

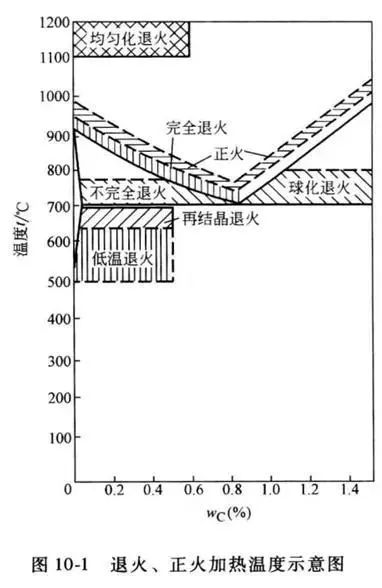

The normalizing is a process in which the sub-co-analysis steel is heated to Ac3 30~50 ℃, the co-analysis steel is heated to Ac1 30~50 ℃, and the over-co-analysis steel is heated to Accm 30~50 ℃ and then air cooled. The normalizing cooling rate is larger than that of annealing.

1. The basic concept of normalizing

normalizing is the heating of hypoeutectoid steel to Ac330~50 ℃, eutectoid steel heated to Ac130~50 ℃, hypereutectoid steel heated to AccmThe process of air cooling after heat preservation at 30~50 ℃. The normalizing cooling rate is larger than that of annealing.

The purpose of normalizing:

(1) For low and medium carbon steels (≤ 0.6%C), the purpose is the same as for annealing.

(2) For over-co-analysis steel, it is used to eliminate the mesh secondary carburizing body and prepare the tissue for the ball annealing.

(3) Final heat treatment of ordinary parts.

To improve the cutting performance, normalizing for low carbon steel, annealing or normalizing for medium carbon steel, and spheroidizing annealing for high carbon steel.

2. The basic concept of annealing

The steel parts are heated to a temperature higher or lower than the critical temperature of the steel, and then cooled slowly with the furnace or buried in a medium with poor thermal conductivity after proper insulation, so as to obtain a heat treatment process close to the equilibrium state organization.

The purpose of annealing:

(1) Adjust the hardness to facilitate cutting. Suitable for processing hardness of 170-250HB;

(2) Eliminate internal stress and prevent deformation during processing;

(3) Refine the grain and prepare the tissue for the final heat treatment.

There are many types of annealing, commonly used are full annealing, isothermal annealing, spheroidizing annealing, diffusion annealing, stress relief annealing, recrystallization annealing.

3. The basic concept of quenching

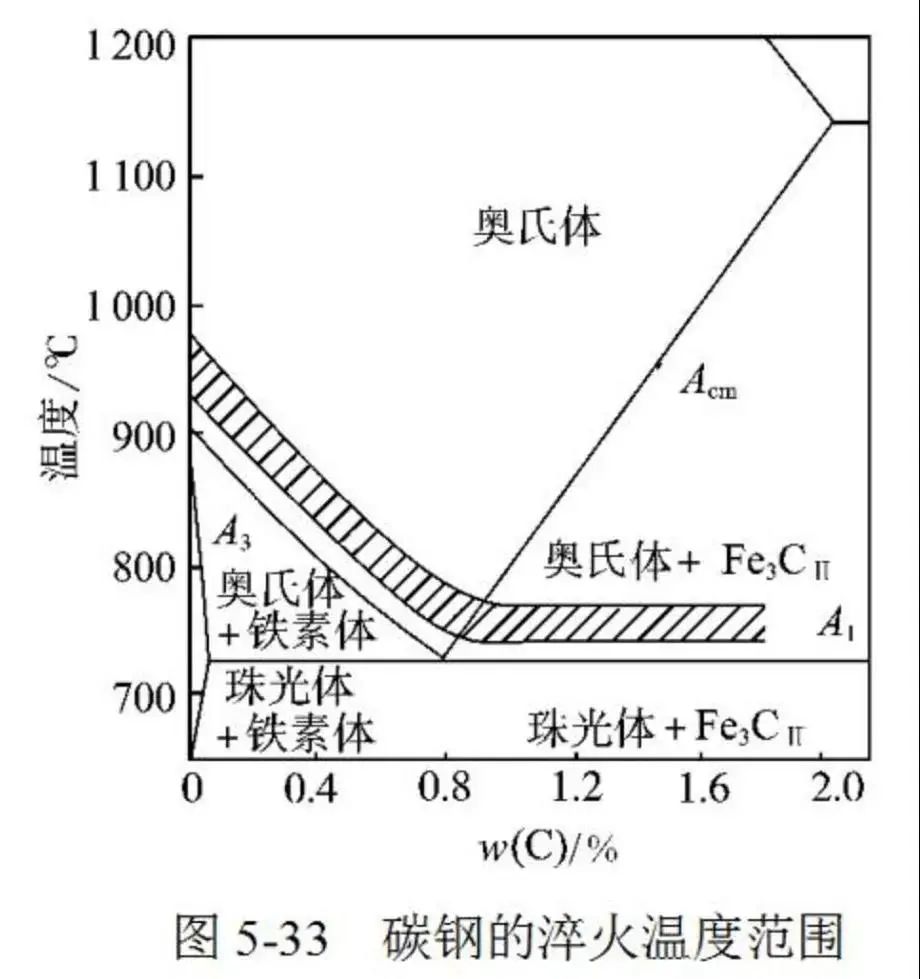

Heat the steel to Ac3(hypoeutectoid steel) or Ac1(hypereutectoid steel) above (30~50)℃, the operation process of rapid cooling in water or oil after heat preservation is called quenching. Generally in order to obtain martensite structure, followed by appropriate tempering, in order to obtain a variety of performance.

The quenching temperature of carbon steel is mainly determined by the amount of C in the steel according to the Fe-Fe3C phase diagram to determine, as shown in the figure for the quenching heating temperature range.

When quenching a metal, it is necessary to heat the metal workpiece to an appropriate temperature and hold it for a period of time, and then immerse it in the quenching medium for rapid cooling. According to the cooling rate of quenching, the commonly used quenching medium is water, aqueous solution, mineral oil, molten salt, molten alkali, etc.

Commonly used quenching methods include single-liquid quenching, two-liquid quenching, graded quenching, and isothermal quenching.

4. The basic concept of tempering

Tempering refers to the process of heating hardened steel to a temperature below A1 for an appropriate time and then cooling in air or water.

Purpose of tempering:

(1) Reduce or eliminate quenching internal stress to prevent deformation or cracking

(2) to obtain the required mechanical properties. Hardened steel generally high hardness, brittleness, tempering can adjust the hardness, toughness.

(3) stable size. Quenched M and A' are non-equilibrium tissue, there is a tendency to spontaneously change to equilibrium tissue. Tempering can make M and A' into a balanced or close to balanced tissue to prevent deformation during use.

(4) for some high hardenability of steel, air cooling can be quenched, such as the use of tempering softening can reduce the hardness, but also shorten the softening cycle.

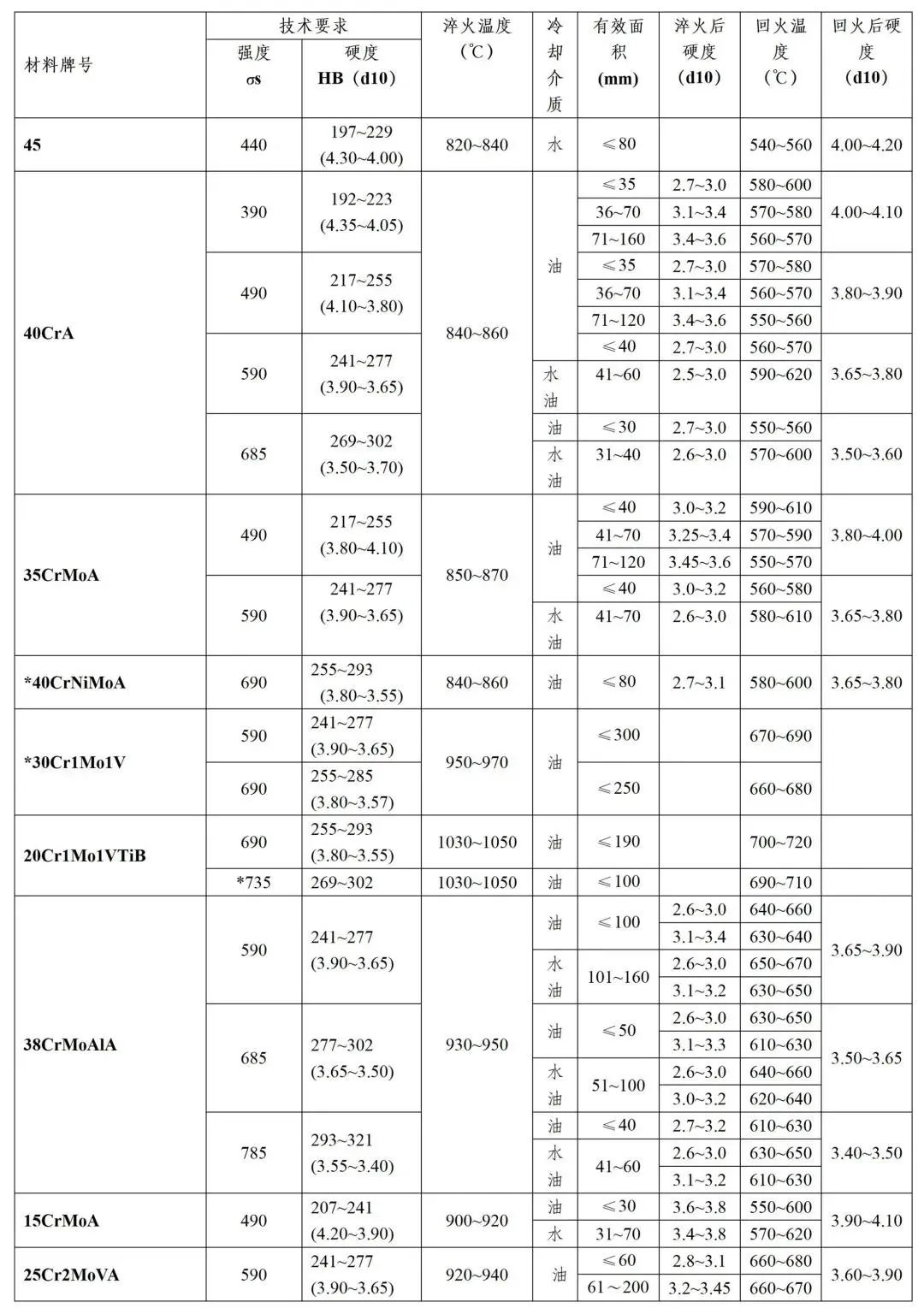

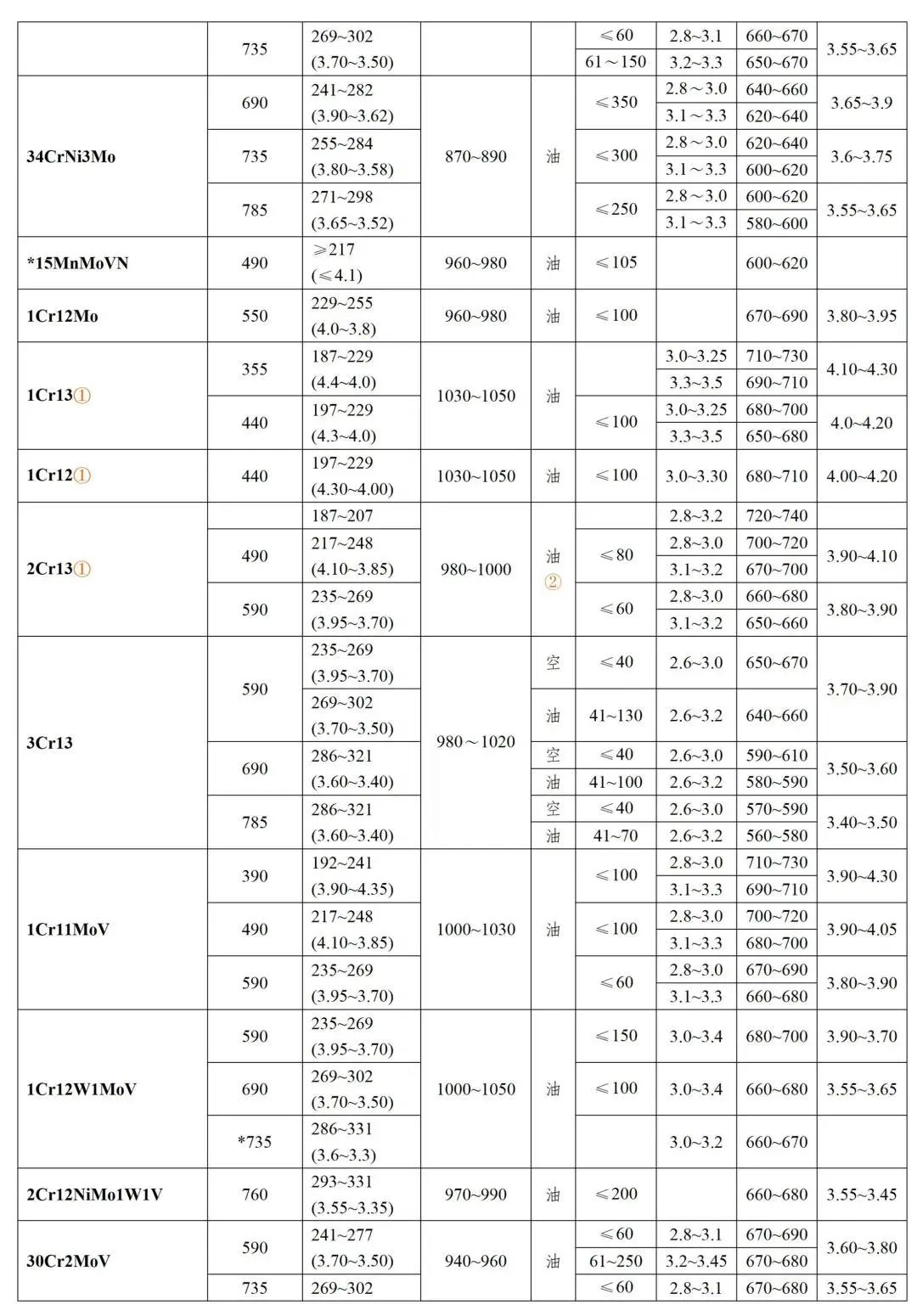

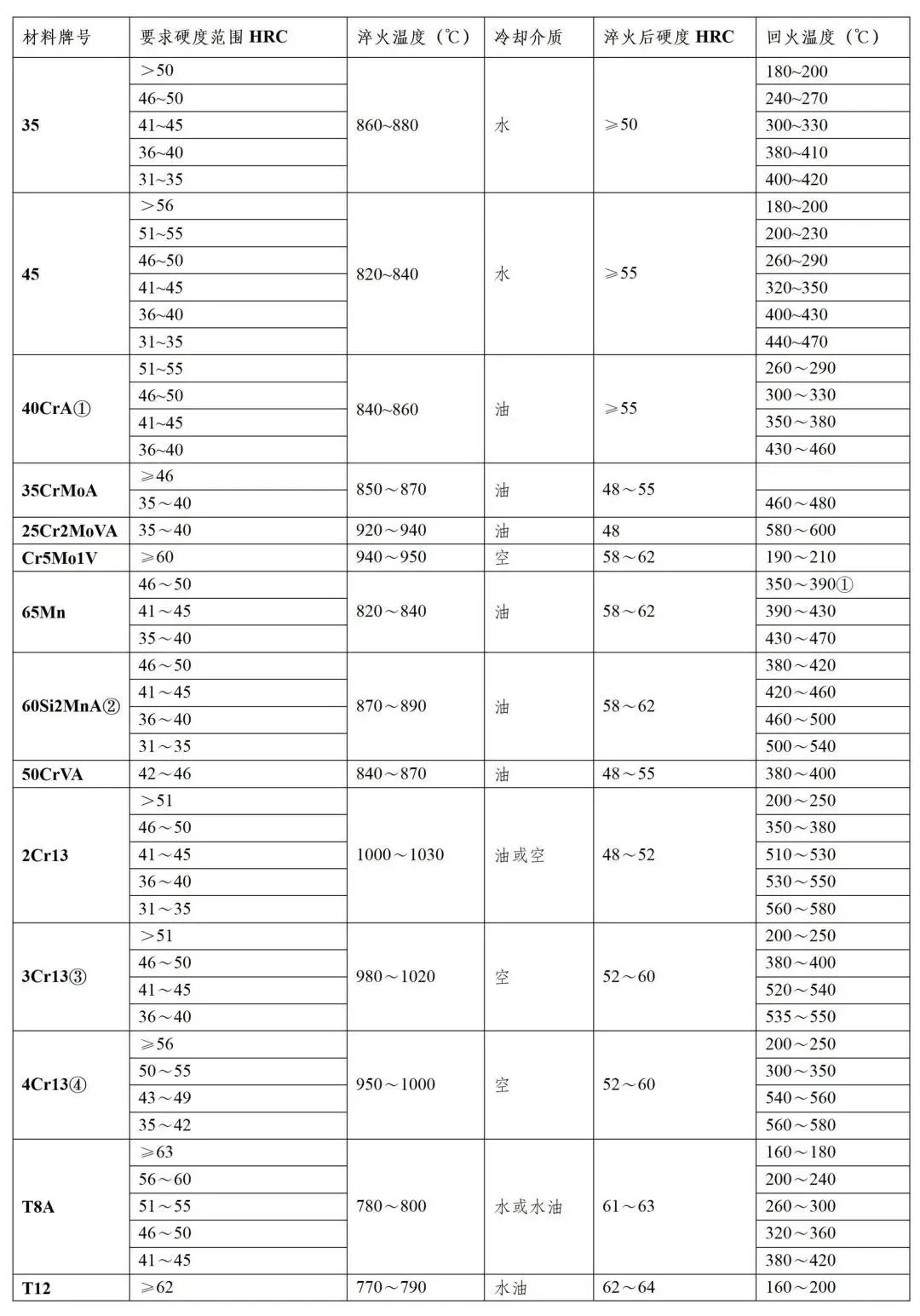

5. Commonly used steel quenching, tempering temperature

Table 1 Steel grades requiring comprehensive properties

Note:

① When using Japanese materials, the quenching temperature is 960~980 ℃, and the tempering temperature is allowed to be 10~30 ℃ higher than the temperature in the table.

② Air cooling can be used if the effective section is less than 20mm.

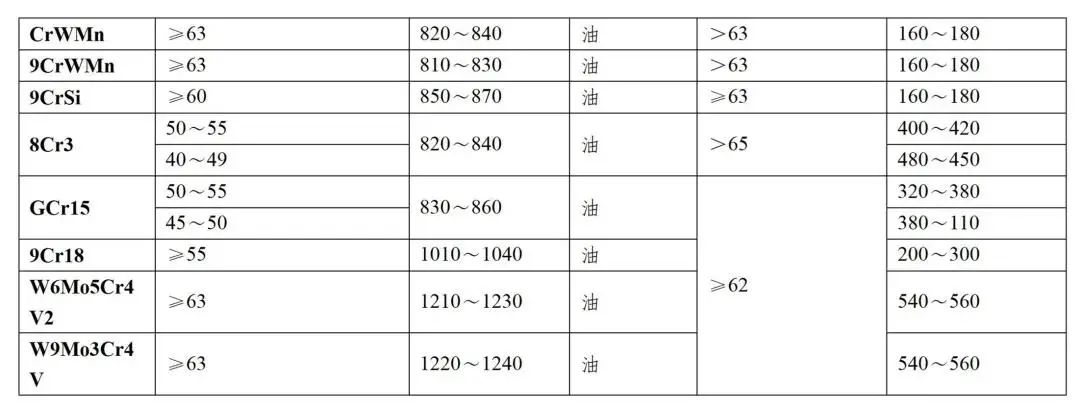

Table 2 Steel grades requiring hardening (new HRC>30)

Note:

① Oil cooling after tempering.

② quenching heating to be protected to prevent decarburization.

③ Tempering brittle zone is 500~510 ℃, which is strictly prohibited.

④ Tempering brittle zone is 470~530 ℃, which is strictly prohibited.

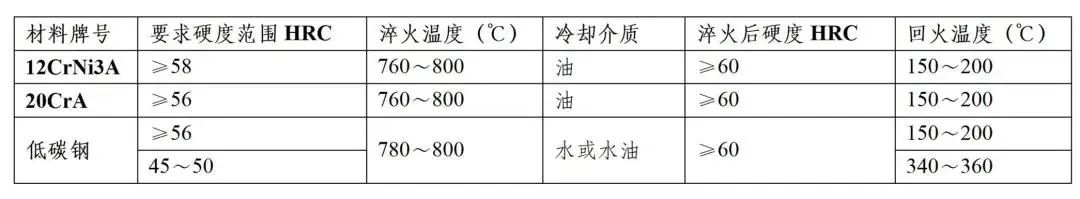

Table 3 Steel grades required for carburizing and hardening

A few notes:

(1) The quenching and tempering temperature range provided in Table 1-3 is used for selecting parameters according to specific conditions during production, and is not the allowable temperature deviation of a certain furnace.

(2) All water-cooled steel grades (except austenitic steel) shall be tempered in time to prevent cracking.

(3) σ in Table 1sThe value is σ0.2The value.

(4)45, 35CrMoA, 40CrNiMoA In order to ensure that the sampling parts are qualified, the hardness of the blank for inspection is allowed to be appropriately improved.

(5) For induction heating, the quenching temperature of rapidly heated parts is allowed to be appropriately increased.

(6) Those marked with * in the table have not been used or rarely used in production, and their parameters are not mature enough to be further verified in production, and modifications are allowed on the basis of verification in production.

(7) If the cooling is water → oil in Table 1~3, it is allowed to use water → air → water instead. The specific method is: after water cooling for a period of time, lift the parts into the air (after allowing the parts to heat up) and then enter the water to continue cooling.

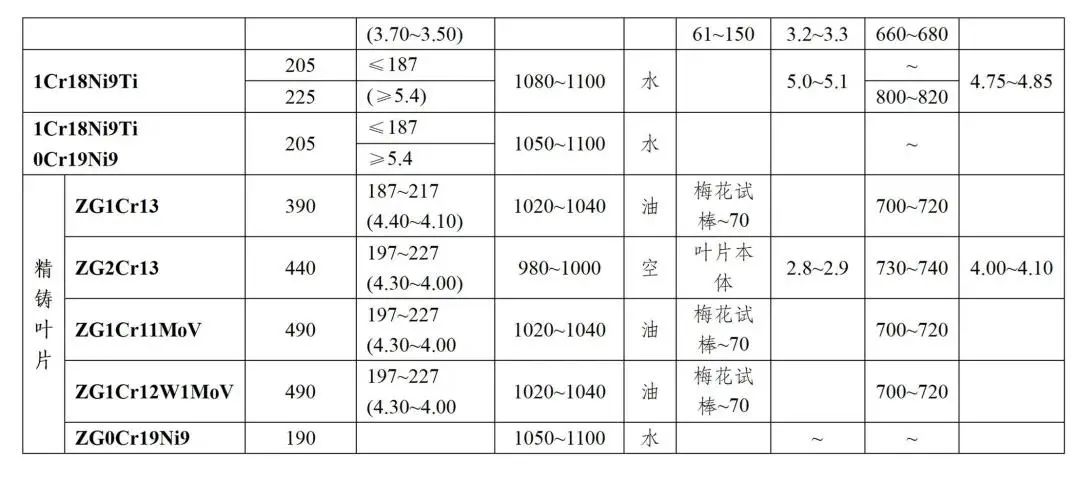

6. Commonly used steel normalizing, tempering and annealing temperature

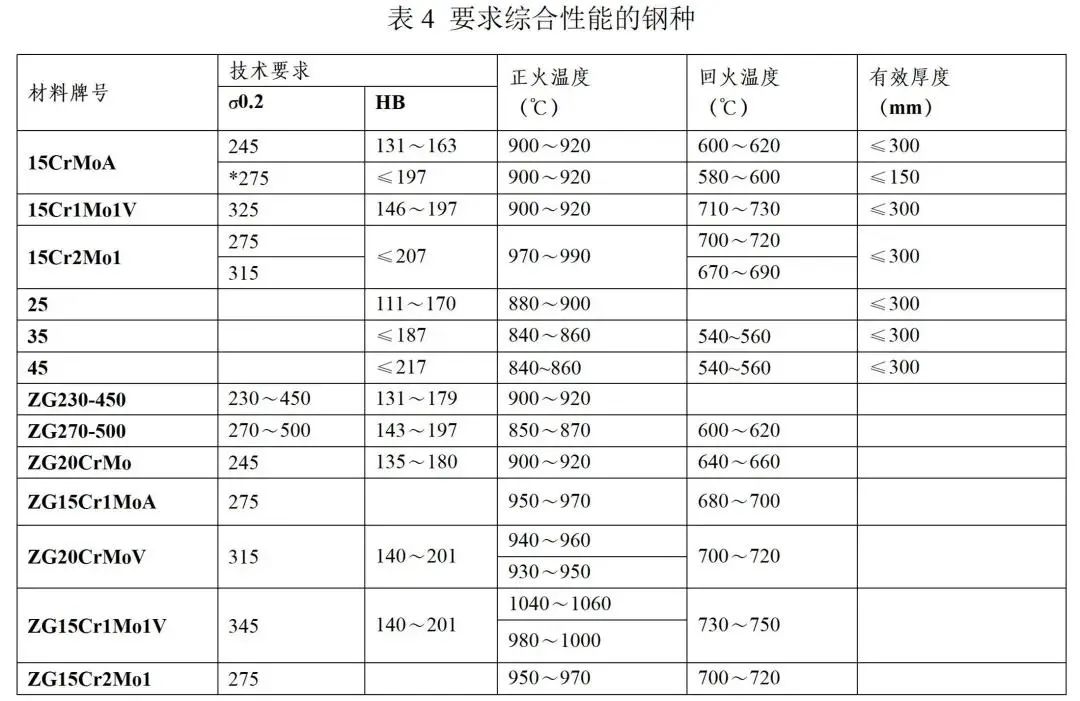

Table 4 Steel grades requiring comprehensive properties

Table 5 Other steel grades

Note:

① Used to eliminate coarse crystal.

② I is used for softening; II is used for grain refinement.

③ Used to eliminate coarse crystal.

④ normalizing for the elimination of overheating structure and network carbide.

The mold renovation annealing temperature is 720~740 ℃.

The mold renovation annealing temperature is 710~730 ℃.

A few notes:

(1) The normalizing, tempering and annealing temperature ranges listed in Table 5 are selected for production within this interval, not the allowable temperature deviation of a furnace, and the middle limit is generally selected.

(2) The tempering specified in Table 4 shall be carried out after normalizing according to the requirements of technical conditions. The tempering specified in Table 5 may be carried out after normalizing or separately after forging, depending on the specific situation.

(3) the normalizing temperature of the network carbide in the carburized layer shall be 860~880 ℃.

Next article

Previous article

Previous article