News Details

A special steel enterprise specializing in the production, research and development and sales of high alloy steel forgings

03

2022

-

11

Advantages of Electric Arc Furnace Bottom Blowing Technology (DPP)

Author:

The electric arc furnace bottom blowing technology (DPP) was first applied on the 110t electric arc furnace of Thyssen Special Steel Company in Germany in 1980, with the following advantages.

Electric arc furnace bottom blowing technology (DPP) was first applied on the 110t electric arc furnace of Thyssen Special Steel Company in Germany in 1980. It mainly has the following advantages:

(1) Promote the melting of scrap steel, reduce the soft melting phenomenon of the cold zone, in order to help eliminate the cold zone in the process of electric arc furnace steelmaking.

(2) It is beneficial to improve the reaction speed of the steel slag interface, contribute to the adsorption and removal of inclusions in the electric arc furnace roughing steel, increase the reaction speed of dephosphorization and decarburization, and have positive significance for shortening the smelting cycle.

(3) The movement speed of molten steel in the molten pool is increased, which helps to eliminate the temperature imbalance in the molten pool and can reduce the tapping temperature.

(4) Due to the stirring effect of bottom blowing, the reaction at the steel slag interface tends to be more balanced, which reduces the iron oxide content in the slag, which is conducive to the reduction of iron consumption.

(5) Due to the reduction of the tapping temperature of the electric arc furnace and the content of iron oxide in the slag, the life of the furnace lining is improved.

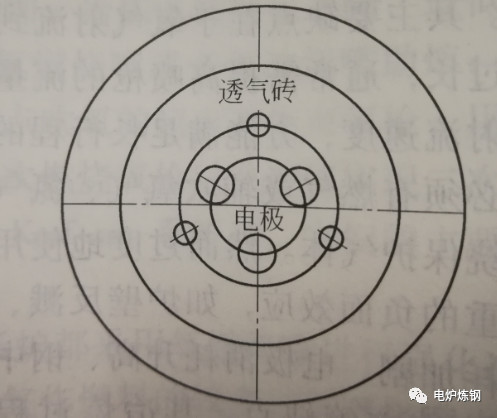

Because of the above advantages, the bottom blowing technology of electric arc furnace has been paid attention to and developed in recent years. The bottom blowing technology is mainly to install three air-permeable bricks at an angle of 120 at the bottom of the electric arc furnace, and fill between the air-permeable bricks and the set bricks with furnace bottom tamping materials.

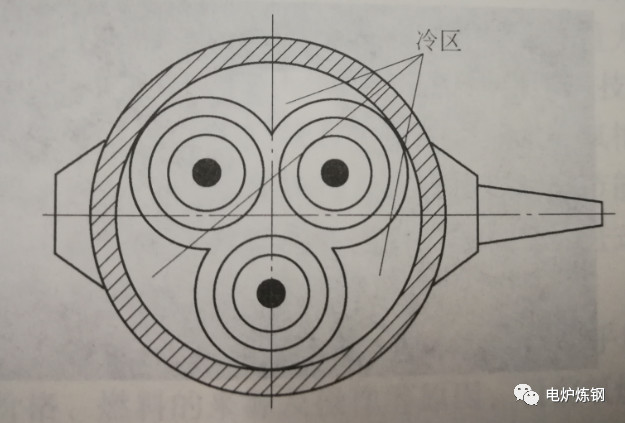

When the first furnace is used, it does not supply air, and the permeable brick can be replaced when it is seriously damaged. The replacement method is similar to the method of replacing the EBT set brick. The cold zone of the electric arc furnace is shown in Figure 1, and the distribution of bottom blowing bricks is shown in Figure 2.

Fig.1 Distribution of cold zone in electric arc furnace smelting

Fig.2 Distribution diagram of bottom blowing brick

The general gas supply pressure is between 0.3-1.2MPa, and the flow rate (standard state) of the stirring gas is controlled at 0.002-0.001 m3/(min · t). The gas used in the bottom blowing is nitrogen, carbon dioxide gas and argon. The use of argon as the bottom blowing gas can reduce the nitrogen content in the steel. In order to reduce costs, some manufacturers use different gas media at different stages. In Oberhause, when producing steel grades that are not sensitive to nitrogen, nitrogen is blown when the molten steel temperature is below 1550 ℃, and argon is blown at 1550-1650 ℃. Because the molten steel temperature is below 1550 ℃, the amount of nitrogen absorbed by molten steel is small.

Previous article

Previous article