News Details

A special steel enterprise specializing in the production, research and development and sales of high alloy steel forgings

03

2022

-

11

Identification Method of Quenching Crack and Non-Quenching Crack

Author:

Quenching crack is a common quenching defect, which is caused by many reasons. Since the defects of heat treatment start from the product design, the work of preventing cracks should start from the product design. It is necessary to correctly select materials, reasonably carry out structural design, put forward appropriate heat treatment technical requirements, properly arrange the process route, select reasonable heating temperature, holding time, heating medium, cooling medium, cooling method and operation mode.

Quenching crack is a common quenching defect, which is caused by many reasons. Since the defects of heat treatment start from the product design, the work of preventing cracks should start from the product design. It is necessary to correctly select materials, reasonably carry out structural design, put forward appropriate heat treatment technical requirements, properly arrange the process route, select reasonable heating temperature, holding time, heating medium, cooling medium, cooling method and operation mode.

1. material aspect

1. Carbon is an important factor affecting the tendency of quenching cracking. The carbon content increases, the MS point decreases, and the quenching cracking tendency increases. Therefore, in order to meet the basic properties such as hardness, strength conditions, should try to choose a lower carbon content, in order to ensure that it is not easy to crack.

2. The influence of alloying elements on quenching cracking tendency is mainly reflected in the influence on hardenability, MS point, grain size growth tendency and decarburization. The alloying elements affect the quenching cracking tendency by affecting the hardenability. In general, the increase in hardenability, quenching cracking increased, but the increase in hardenability at the same time, but can use the cooling capacity of the weak quenching medium to reduce the quenching deformation method to prevent the deformation of complex parts and cracks. Therefore, for parts with complex shapes, in order to avoid quenching cracks, it is a better solution to choose steel with good hardenability and use quenching medium with weak cooling capacity. Alloying elements have a great influence on the MS point. Generally speaking, the lower the MS, the greater the tendency of quenching cracking. When the MS point is high, the martensite generated by phase transformation may be self-tempered immediately, thus eliminating part of the phase transformation stress and avoiding quenching cracking. Therefore, when the carbon content is determined, a small amount of alloying elements should be selected, or steel grades containing elements that have less influence on the MS point.

When selecting steel, overheating sensitivity should be considered. Steel that is more sensitive to overheating is prone to cracks, so attention should be paid to the selection of materials.

Structural Design of 2. Parts

1. Uniform section size. Parts with a sharp change in cross-sectional size will crack due to internal stress during heat treatment. Therefore, the design to avoid section size mutation. The wall thickness should be uniform. If necessary, holes can be made in thick-walled parts that are not directly related to the use. The hole should be made through hole as far as possible. For parts with different thicknesses, split design can be carried out and assembled after heat treatment.

2. Fillet transition. When the parts have edges, sharp corners, grooves and transverse holes, these parts are prone to stress concentration, resulting in parts of the quenching crack. For this reason, the parts should be designed as far as possible without stress concentration, and the sharp corners and steps should be processed into rounded corners.

3. The difference in cooling speed caused by the shape factor. The fast and slow cooling speed of parts during quenching varies with the shape of the parts. Even in different parts of the same part, the cooling rate will be different due to various factors. Therefore, try to avoid excessive cooling differences to prevent quenching cracks.

Technical conditions for 3. heat treatment

1, try to use local quenching or surface hardening.

2. Adjust the local hardness of the quenched parts reasonably according to the service conditions of the parts. When the local quenching hardness requirement is low, try not to force the overall hardness to be consistent.

3, pay attention to the quality effect of steel.

4. Avoid tempering in the first type of tempering brittle zone.

4. reasonable arrangement of process route and process parameters

Once the material, structure and technical conditions of the steel parts are determined, the heat treatment process personnel will carry out process analysis and determine the reasonable process route, that is, correctly arrange the position of the preparatory heat treatment, cold working and hot working processes and determine the heating parameters.

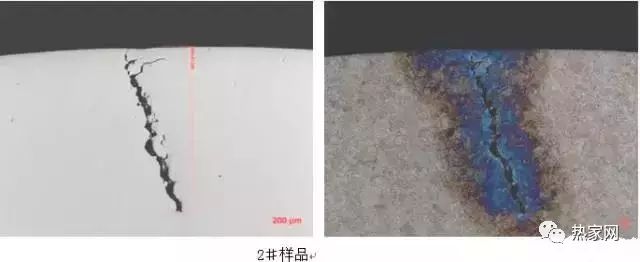

Quench crack:

1. Under 500X, it is serrated, with wide cracks at the beginning and small to no cracks at the end.

2. Micro analysis:

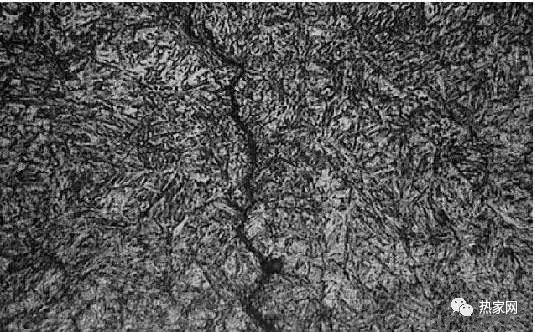

Abnormal metallurgical inclusions, the crack morphology is serrated extension; after corrosion with 4% nitric acid alcohol, there is no decarburization phenomenon, the microscopic morphology is shown in the following figure:

1# sample

No abnormal metallurgical inclusions were found at the cracks, no decarburization, and the cracks extended serrated, with typical characteristics of quenching cracks.

Analysis conclusion:

1. The composition of the sample meets the standard requirements and corresponds to the original heat number composition.

2. By microscopic analysis, no abnormal metallurgical inclusions were found at the cracks of the sample, no decarburization phenomenon, and the cracks extended serrated, with the typical characteristics of quenching cracks.

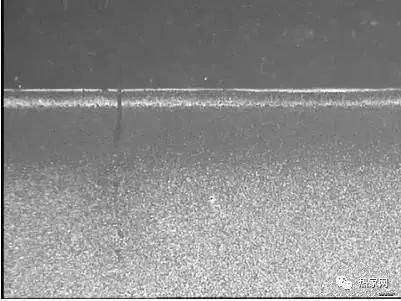

Forging crack:

1. Cracks caused by typical material reasons, the edge is oxide,

2. Microscopic observation

The white and bright layer on the surface shall be the secondary quenching layer, and the deep black layer under the secondary quenching layer shall be the high temperature tempering layer.

Analysis conclusion:Cracks with decarburization should be distinguished from raw material cracks. Generally, cracks with decarburization depth greater than or equal to surface decarburization depth are raw material cracks, and forging cracks with decarburization depth less than surface decarburization depth.

Next article

Previous article

Previous article